Phone

Top

How can I truly distinguish the quality of the cable wires is good and secondary

2020-02-01

Foot rice may be more difficult to be found on the rice number, because customers generally do not actually measure the amount of rice numbers, and the same use of measurement method can know whether the cable is full rice. Or it is also a good way to print the rice label when it is produced by the factory, but it should be noted that there is no way to print the rice label with a line with a diameter of less than 5mm.

Footmark copper is a precious metal. If you lose a little on the diameter of copper, you can reduce the cost of a lot of raw materials. In this way, you need to measure the diameter of the copper wire with a thousand feet. If there is no thousand -point feet, the simpler way is to call the entire roll wire and see if it is much lighter than the high -quality cable. Or you can refer to the nominal weight given by the factory. The nominal weight given by some factories is low, and naturally it cannot guarantee the quality of the product.

How to distinguish the quality inside the wire and cable:

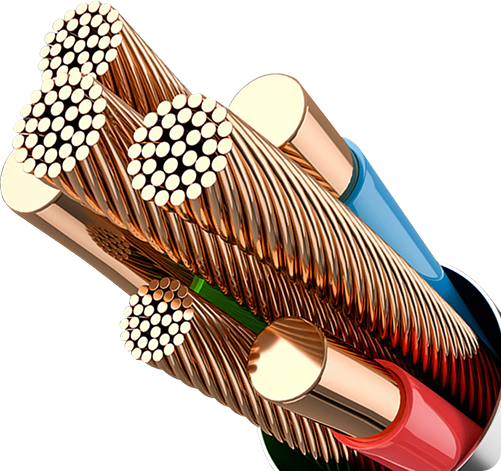

The high -quality cable of copper uses high -purity anaerobic copper. The copper core color is bright, and the surface of the poor copper wire is darker.

Out of the air

Plastic plastic uses high -quality native plastic. It has good bending performance. Bending the cable does not produce texture. The poor recycling plastic will appear obvious texture after a few times.

Cable equipment

In order to ensure the round neat cable, the polycrus cable will add filling to the online core, and the thickness of the protective cover will be thicker. And the protective cover is thin.

Cable equipment

Multi -stranded copper wires will be bundled during production to improve the tensile performance of the copper core, round neatness, electrical performance, and closeness to the insulation layer. The factory has omitted this step. The method of distinguishing is to cut the core wire of the cable to see if the copper wire inside has a regular twisted coincidence.

The woven belt has a copper network woven layer cable, and the weaving layer accounts for a large part of the cost of cable raw materials. The coverage of the weaving layer directly affects the electrical performance of the cable. At the same time, the tightly woven layer can increase the strength of the cable. The wire and cable are reduced. The electrical performance of the cable decreases in the bending state. Therefore, to see if the woven layer has a high coverage and uniform weaving, it is an important means to distinguish the advantages and disadvantages.

Related News

2023 China Radio Conference opened in Qingdao

On September 14, the 2023 China Radio Conference opened in Qingdao City, Shandong Province. Zhang Yunming, a member of the party group and deputy minister of the Ministry of Industry and Information Technology, attended the opening ceremony and delivered a speech.

"East Digital and West Calculation" makes the digital "footsteps" faster and more stable

What is "East and West Calculation"? Why implement the "East Digital West Calculation" project? How to advance?

Matters that pay special attention should be paid to the cable maintenance test

As a part of the power line, power cables have been widely used because of their low probability of failure, safe and reliable, and flexible qualifying. However, once a failure is caused, the maintenance is difficult and the danger is high, so pay special attention to the maintenance and test.

2023 China Radio Conference opened in Qingdao

On September 14, the 2023 China Radio Conference opened in Qingdao City, Shandong Province. Zhang Yunming, a member of the party group and deputy minister of the Ministry of Industry and Information Technology, attended the opening ceremony and delivered a speech.

"East Digital and West Calculation" makes the digital "footsteps" faster and more stable

What is "East and West Calculation"? Why implement the "East Digital West Calculation" project? How to advance?

Matters that pay special attention should be paid to the cable maintenance test

As a part of the power line, power cables have been widely used because of their low probability of failure, safe and reliable, and flexible qualifying. However, once a failure is caused, the maintenance is difficult and the danger is high, so pay special attention to the maintenance and test.

Looking forward to hearing from you!

CONTACT US

1. Call us

2. Send an email

3. Leave a message

4. Add WeChat or Whatsapp