Phone

Top

BTTZ (rigid fire prevention)

(1) Cable conductor: made of high conductivity metal copper as conductor. (2) insulation layer: The use of high temperature resistant, non-burning inorganic magnesium oxide as insulationmaterial. (3) Metal sheath: The use of copper pipe as a sheath, after special processing has good continuity and bending characteristics, and can beused as a grounding wire. (4) Outer protective layer: if necessary, squeeze a layer of plastic outer protective layer outside the metal copper sheath, the use of low-smokenon-toxic plastic material, with good protection Corrosion characteristics.

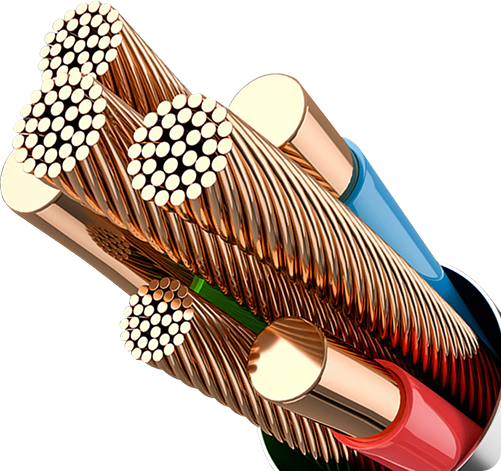

1. Composition of mineral insulated cable

(1) Cable conductor: made of high conductivity metal copper as conductor.

(2) insulation layer: The use of high temperature resistant, non-burning inorganic magnesium oxide as insulationmaterial.

(3) Metal sheath: The use of copper pipe as a sheath, after special processing has good continuity and bending characteristics, and can beused as a qrounding wire.

(4) Outer protective layer: if necessary, squeeze a layer of plastic outer protective layer outside the metal copper sheath, the use of low-smokenon-toxic plastic material, with qood protection Corrosion characteristics.

2.Product presentation method

| Grade | Rated Voltage | Model | Name | Core | Cross Section mm2 |

| Light load |

500V (450/750V) |

BTTQ | Lightweight copper core copper sheathed mineral insulated cable | 1、2、3、4、7 | 1.0-4.0 |

| BTTVQ | Lightweight copper core copper sheathed PVC sheathed mineral insulated cable | 1、2、3、4、7 | 1.0-4.0 | ||

| Overload |

700V (600/1000V) |

BTTZ | Heavy copper core copper sheathed mineral insulated cable | 1、2、3、4、7、12、19 | 1.5-400 |

| BTTVZ | Heavy copper core copper sheathed PVC sheathed mineral insulated cable | 1、2、3、4、7、12、19 | 1.5-400 |

Note: Multi-core cables with a cross-section of 25 mm2 or more are all composed of single-core cables.

3. mineral insulated cable carrying capacity and product technical parameters

| Model |

Number of × section mm |

Cable outer diameter | Rated current carrying capacity |

Copper sheath cross-sectional mm2 |

Finished cable madength (For reference only) mm |

Approximate weight | |||

|

bare cable mm |

Plastic sheath mm |

bare cable mm |

Plastic sheath mm |

bare cable mm |

Plastic sheath mm |

||||

|

BTTQ (BTTVQ) |

2×1.0 | 5.1 | 6.4 | 17.5 | 19.5 | 6.0 | 800 | 104 | 125 |

| 2×1.5 | 5.7 | 7.0 | 22.5 | 36 | 7.1 | 800 | 130 | 153 | |

| 2×2.5 | 6.6 | 7.9 | 30 | 33 | 9.4 | 800 | 179 | 205 | |

| 2×4 | 7.7 | 9.2 | 40 | 44 | 12.1 | 600 | 248 | 287 | |

| 3×1.0 | 5.8 | 7.1 | 15 | 16.5 | 7.6 | 800 | 135 | 159 | |

| 3×1.5 | 6.4 | 7.7 | 19 | 21 | 8.9 | 800 | 168 | 193 | |

| 3×2.5 | 7.3 | 8.8 | 25 | 28 | 10.7 | 800 | 224 | 261 | |

| 4×1.0 | 6.3 | 7.6 | 14.5 | 16 | 8.8 | 800 | 161 | 187 | |

| 4×1.5 | 7.0 | 8.3 | 19 | 21 | 10.2 | 800 | 202 | 230 | |

| 4×2.5 | 8.1 | 9.6 | 25 | 25 | 12.8 | 600 | 278 | 319 | |

| 7×1.0 | 7.6 | 9.1 | 10 | 11 | 11.6 | 600 | 233 | 271 | |

| 7×1.5 | 8.4 | 9.9 | 12.5 | 14 | 13.3 | 600 | 291 | 333 | |

| 7×2.5 | 9.7 | 11.2 | 17 | 21 | 17.4 | 600 | 407 | 455 | |

Note: When the cable is delivered, the actual delivery length shall prevail.

| Model |

Number of × section mm |

Cable outer diameter | Rated current carrying capacity |

Copper sheath cross-sectional mm2 |

Finished cable madength (For reference only) m |

Approximate weight | |||

|

bare cable mm |

Plastic sheath mm |

bare cable mm |

Plastic sheath mm |

bare cable mm |

Plastic sheath mm |

||||

| BTTZ (BTTVZ) |

2×1.0 | 7.3 | 8.8 | 17.5 | 19.5 | 10.9 | 800 | 165 | 198 |

| 2×1.5 | 7.9 | 9.4 | 23.5 | 26 | 12.5 | 800 | 230 | 270 | |

| 2×2.5 | 8.7 | 10.2 | 32 | 36 | 14.6 | 800 | 284 | 327 | |

| 2×4 | 9.8 | 11.3 | 42 | 47 | 17.6 | 600 | 365 | 413 | |

| 2×6 | 10.9 | 12.4 | 54 | 60 | 20.9 | 600 | 459 | 512 | |

| 2×16 | 14.7 | 16.2 | 98 | 109 | 34.1 | 500 | 871 | 941 | |

| 2×25 | 17.1 | 19.1 | 128 | 142 | 43.4 | 450 | 1201 | 1299 | |

| 3×1 | 7.7 | 9.2 | 15 | 16.5 | 11.9 | 800 | 214 | 252 | |

| 3×15 | 8.3 | 9.8 | 20 | 22 | 13.6 | 800 | 260 | 302 | |

| 3×25 | 18.2 | 20.2 | 108 | 120 | 48.4 | 450 | 1460 | 1564 | |

| 4×1 | 8.4 | 9.9 | 14.5 | 16 | 13.8 | 800 | 312 | 358 | |

| 4×1.5 | 9.1 | 10.6 | 20.5 | 23 | 15.8 | 800 | 312 | 358 | |

| 4×2.5 | 10.1 | 11.6 | 27 | 30 | 18.5 | 600 | 395 | 444 | |

| 4×4 | 11.4 | 12.9 | 36 | 40 | 22.9 | 600 | 519 | 574 | |

| 4×6 | 12.7 | 14.2 | 46 | 51 | 26.7 | 600 | 658 | 719 | |

| 4×10 | 14.8 | 16.3 | 61 | 68 | 34.4 | 500 | 927 | 997 | |

| 4×16 | 17.3 | 19.3 | 80 | 89 | 45.8 | 450 | 1353 | 1455 | |

| 4×25 | 20.1 | 22.6 | 104 | 116 | 56.0 | 400 | 1822 | 1956 | |

| 7×1 | 9.9 | 11.4 | 10 | 11 | 18.1 | 600 | 324 | 376 | |

| 7×1.5 | 10.8 | 12.3 | 12.5 | 14 | 20.7 | 600 | 404 | 463 | |

| 7×2.5 | 12.1 | 13.6 | 17 | 21 | 24.7 | 600 | 766 | 840 | |

| 7×4 | 13.6 | 15.1 | 24.5 | 27.2 | 30.3 | 500 | 752 | 840 | |

| 12×1 | 13 | 14.5 | 9.2 | 10.1 | 28.1 | 600 | 766 | 840 | |

| 12×1.5 | 14.1 | 15.6 | 11.5 | 12.9 | 31.9 | 500 | 981 | 1075 | |

| 12×2.5 | 15.6 | 17.6 | 15.6 | 19.3 | 37.6 | 500 | 1260 | 1385 | |

| 19×1 | 15.2 | 17.2 | 8.1 | 8.9 | 35.8 | 500 | 1066 | 1169 | |

| 19×1.5 | 16.6 | 18.6 | 10.1 | 11.3 | 41.6 | 450 | 1364 | 1496 | |

Note: When the cable is delivered, the actual delivery length shall prevail.

Our advantage

High transmission efficiency

Cables can efficiently transmit electrical energy and signals, providing stable power supply and communication transmission.

Strong anti-interference ability

The insulation layer of the cable can effectively isolate external electromagnetic interference and provide reliable signal transmission and power distribution.

Safe and reliable

The cables are professionally designed and manufactured, have good heat resistance, pressure resistance, and weather resistance, and can work safely and reliably under various environmental conditions.

Cost effective

Compared with other power transmission methods, such as aerial power transmission, cables have the advantages of small footprint and low line loss, saving resources and costs.

Flexible and diverse

Cables can be customized according to different needs, including the selection of conductor materials, insulation layer materials, number of cores, cross-sectional size and other parameters, and are suitable for different scenarios and applications.

Long life

High-quality cables are properly designed and manufactured to have a long service life, reducing maintenance and replacement costs.

Energy saving

Cables do not need to burn fuel when transmitting electrical energy, do not produce waste gas and environmental pollution, and meet the requirements of sustainable development.

Understanding Requirements

Providing Custom Solutions

Providing Samples and Technical Support

Ordering and Production

Logistics and After-Sales Service

Looking forward to hearing from you!

CONTACT US

1. Call us

2. Send an email

3. Leave a message

4. Add WeChat or Whatsapp

Related Products

Related Products